RV Solar Charge Controllers Explained: How They Work, Types, and the Pros & Cons of Each

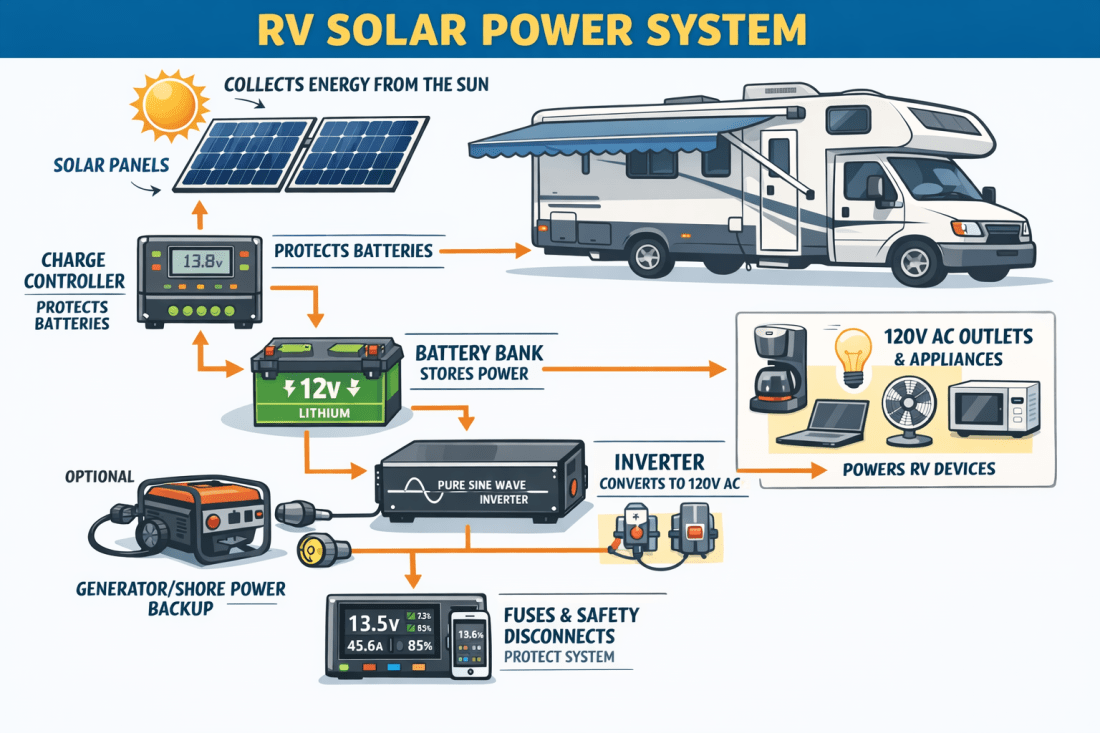

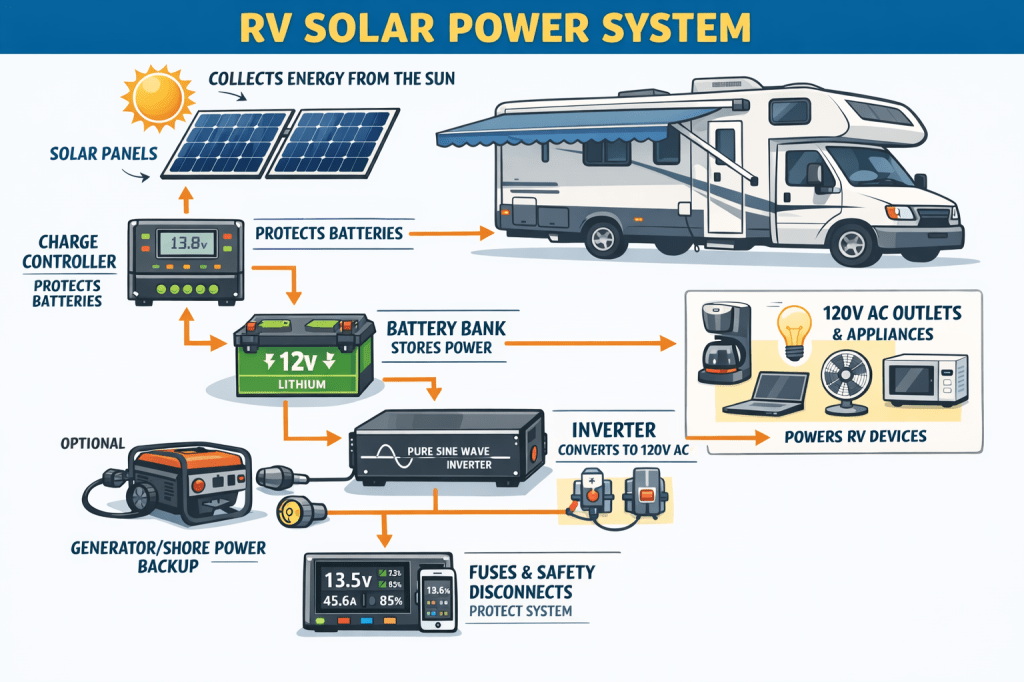

A solar charge controller is one of the most important — and most misunderstood — components in an RV solar system. While solar panels generate power and batteries store it, the charge controller acts as the brain and safety gatekeeper between them.

Without a proper charge controller, batteries can be damaged, solar panels can be wasted, and system efficiency can drop dramatically.

This article explains:

- What a solar charge controller does

- How it operates in real RV conditions

- The two main types of charge controllers

- The advantages and disadvantages of each

- How to choose the right controller for your RV

What Is a Solar Charge Controller?

A solar charge controller regulates the voltage and current coming from your solar panels before it reaches your batteries.

In Simple Terms:

- Solar panels can produce more voltage than batteries can safely accept

- The charge controller reduces and manages that power

- It prevents overcharging, overheating, and battery damage

Think of a charge controller as:

A smart valve that fills the batteries safely and efficiently

How a RV Solar Charge Controller Works

Step-by-Step Operation

- Receives power from the solar panels

- Adjusts voltage and current to match battery needs

- Controls charging stages

- Stops charging when batteries are full

- Restarts charging when batteries need it

Typical Charging Stages

- Bulk Stage

- Maximum power sent to batteries

- Fast charging

- Absorption Stage

- Voltage held steady

- Batteries fill slowly and safely

- Float Stage

- Maintains full charge

- Prevents overcharging

(Some systems include an equalization stage for lead-acid batteries.)

Why Charge Controllers Are Critical in RV Systems

RV solar systems experience:

- Changing sunlight conditions

- Temperature swings

- Partial shading

- Varying battery loads

A charge controller constantly adjusts to these conditions to protect your batteries and maximize solar harvest.

The Two Main Types of RV Solar Charge Controllers

There are two primary types used in RV systems:

- PWM (Pulse Width Modulation)

- MPPT (Maximum Power Point Tracking)

1. PWM Charge Controllers

What Is PWM?

PWM controllers reduce panel voltage to battery voltage by rapidly switching the connection on and off.

How PWM Works (Simplified)

- Panel voltage is pulled down to match battery voltage

- Excess voltage is essentially discarded

- Current remains mostly unchanged

Advantages of PWM Controllers

- Lower cost

- Simple design

- Reliable and proven technology

- Works well with small systems

- Minimal electrical noise

Disadvantages of PWM Controllers

- Lower efficiency

- Wasted panel voltage

- Poor performance in cold weather

- Not ideal for larger arrays

- Requires panel voltage to match battery voltage

Best Use Case for PWM

- Small RV solar systems (under ~200W)

- Short cable runs

- Budget-conscious builds

- Warm climates with flat-mounted panels

2. MPPT Charge Controllers

What Is MPPT?

MPPT controllers actively track the optimal voltage and current from the solar panels and convert excess voltage into usable charging current.

How MPPT Works (Simplified)

- Panels operate at their most efficient voltage

- Controller converts extra voltage into more amps

- Batteries receive more total energy

Advantages of MPPT Controllers

- 15–30% more efficient than PWM

- Excellent in cold weather

- Handles higher panel voltages

- Allows longer cable runs

- Maximizes power in low-light conditions

Disadvantages of MPPT Controllers

- Higher upfront cost

- More complex electronics

- Slightly more setup required

Best Use Case for MPPT

- Medium to large RV solar systems

- Winter RVing

- Northern latitudes

- Lithium battery systems

- Roofs with limited space

PWM vs MPPT: Quick Comparison

| Feature | PWM | MPPT |

|---|---|---|

| Efficiency | Lower | Higher |

| Cost | Lower | Higher |

| Cold Weather Performance | Poor | Excellent |

| Panel Voltage Flexibility | Low | High |

| Cable Run Length | Short | Long |

| System Size | Small | Medium–Large |

Battery Type Compatibility

Lead-Acid Batteries

- Work with both PWM and MPPT

- Benefit moderately from MPPT

- Require temperature compensation

Lithium Batteries (LiFePO₄)

- Strongly benefit from MPPT

- Require precise voltage control

- Often include battery communication (BMS)

Real-World RV Scenarios

Weekend or Summer RVers

- PWM may be sufficient

- Simpler and cheaper

Full-Time RVers

- MPPT strongly recommended

- Better efficiency and flexibility

Winter or Northern Latitude RVers

- MPPT is almost essential

- Lower sun angles benefit greatly from voltage conversion

Common Charge Controller Features to Look For

- Battery temperature sensor

- Programmable battery profiles

- Bluetooth or display monitoring

- Load output terminals

- Expandability for future panels

Common Mistakes RVers Make

- Undersizing the charge controller

- Using PWM with high-voltage panels

- Ignoring battery temperature limits

- Mounting controller too far from batteries

- Failing to monitor charging behavior

Final Thoughts: Choosing the Right Charge Controller

The charge controller may not be the most visible part of your RV solar system, but it plays one of the most critical roles. Choosing the right controller protects your batteries, improves efficiency, and ensures your system performs reliably across seasons and locations.

For most modern RV solar systems:

MPPT charge controllers offer the best long-term value, flexibility, and performance.

Day 3060